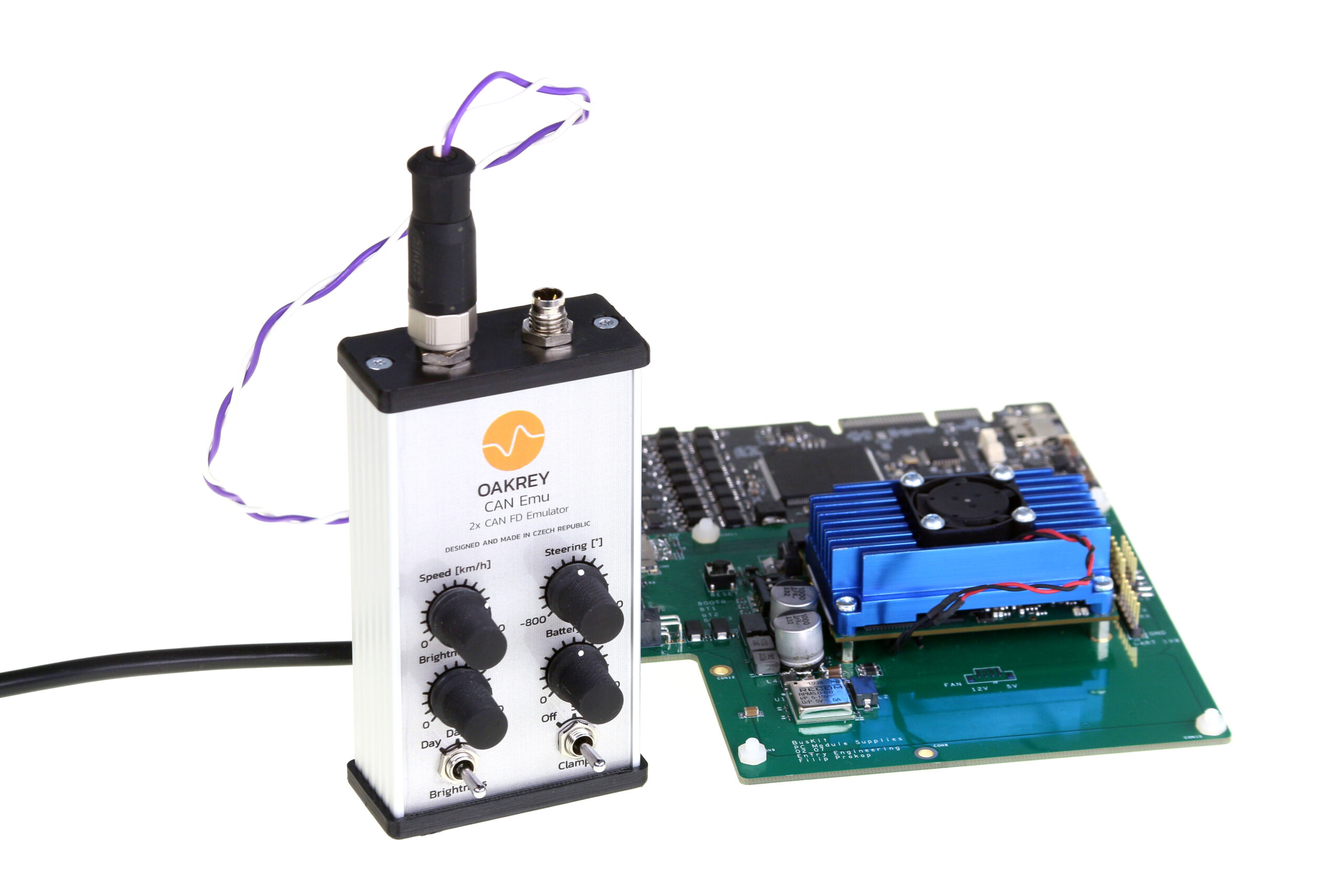

CAN Emu

Two-channel CAN interface device emulator with support for CAN FD standard.

Key features

Support for CAN FD standard.

No-Code programming of complex emulation profiles.

Possibility to power the device directly from the bus.

SDK for easy control of emulations from external software tools.

Use cases

System emulation in controller unit development

You can upload an emulation to the device that mimics the behavior of the system, creating an environment for the unit that is similar to the final system.

The emulated signal values can be controlled based on the settings of physical or virtual elements. Mathematical functions and complex conditional expressions and constraints can be used to define values.

Simulations are created in the DBC Browser software tool.

Emulation of units and sensors during system development

The CAN Emu emulator is used for preliminary implementation into the system before the sensor itself is developed, or for emulation of difficult-to-induce states.

Virtual signals controlled via SDK can also be used for more complex system tests.

No-code emulation profiles can be created using the DBC Browser software tool.

Subsequent control of the signal parameters is done via potentiometers and switches on the device. Functions can be extended to control variables using the Tester software tool or via the supplied SDK.

Equipment and systems testing

The device can be configured as a controlled message generator, and by connecting it to the system, you can induce specific states and test the system. In addition to the mode where the values of the signals in the messages are directly influenced by the user, the device can be configured to respond automatically to certain events on the bus.

Configurable control element

The device can be used as a configurable control element for controlling existing systems and units (for example, controlling motor drivers in the photo).

Another example is the control of a pass-through drying oven where potentiometers control the temperatures in the preheating, drying and cooling zones and the substrate feed rate. Switches switch the substrate dispenser, start-up, drying and cleaning modes.

The device may also include basic state logic capable of responding to, for example, an empty feedstock hopper or a full hopper of dried substrate.

Supported tools

A comprehensive test environment for End-to-End testing with a focus on the automotive industry.

Software for creating and editing CAN Database (DBC) files and creating emulation profiles for CAN Emu devices.

The Software Development Kit contains a dll library and C# examples.

| Model: | CEMU01 |

| Dimensions (h x w x d): | 28 x 59 x 114 mm |

| Data rate: | Full speed USB 2.0 |

| Input voltage: | 5 V DC, max 150 mA, USB |

| 12 – 24 V DC, max 300 mA, M8 | |

| CAN: | 2.0A – standard identifier |

| 2.0B – extended identifier | |

| FD – 5 Mbit/s | |

| ISO 11898-5:2007 | |

| ISO 11898-2:2016 SAE J2284-4/5 | |

| Supported systems: | 12 V and 24 V |

| Operating temperature: | −10 to +70 °C |

Extended operating temperature: | −40 to +85 °C |

| Storage temperature: | −40 to +85 °C |

| Relative humidity: | 0 – 90% |

| Operating system: | Windows 8.1, 10 |

| Weight without cabling: | 155 g |

| EMC/EMI standards: | IEC 61000-4-2, level 4 |

| CAN bus voltage level: | ±48 V (with disconnected terminating resistors) |

| ±12 V (with terminating resistors attached at a maximum filling factor of 1:4) |

| Included: | CAN Emu, |

| 2x cable harness M8 – DSUB9 | |

| cable harness USB A – USB B, | |

| mounting bracket, | |

| user manual, | |

| Quick Start Guide. | |

| Accessories available for purchase: | DIN rail mounting bracket, |

| spare cable assemblies (optional length). |

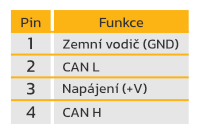

Connector M8S (CAN)

|  |

Wire connector – SAL-8-RKC4-S5,5 .

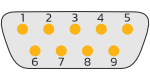

Connector DSUB9 (CAN)

|  |

*The product is sold through the distributor Entry Engineering s.r.o.

Still ongoing development

We are constantly developing or adapting our equipment to our clients’ requirements. If you are interested in the equipment, but some of its parameters do not meet your requirements, we will be happy to design and implement individual modifications for you.